by Tom Keefe | Dec 16, 2022 | Digital Signage, DVLED, Uncategorized

Part 1: Got Spares?

Topic: The importance of having spares when purchasing / commissioning a DVLED video wall..

My wife is very particular. When we were planning for our wedding, she suggested that me and my groomsmen wear black suits. I said…

“Great! They’ve all got a black suit already. One less thing to worry about. Right?”

Wrong.

My wife explained to me that black is not black. She pointed out that if you have seven men stand next to each other in seven different black suits, then the shades of black will be noticeably different. Apparently, this would be bad for our wedding photos.

The point is – she was right. As usual. The difference of one shade of black next to another is very plain to see to even the most untrained eye. She had me. I had to make the call to my groomsmen, saying, “Sorry fellas, you’ve all got to go out and get new black suits.”

LED Panels & Batching

It’s the same with LEDs and batching. One batch will not be exactly the same as another in terms of color and calibration, so when taken together on a large video wall and compared directly with another wall made up of another batch of LEDs, there will be noticeable color differences between the two.

To address this problem, dvLED manufacturers will often provide spare modules from the same batch. This way, when a pixel goes out or a module is damaged or in need of repair, the spare can be swapped in to replace the damaged unit. If you select a solid manufacturer with U.S. service centers, they will usually repair your damaged unit and send it back to you under warranty. Once you have the repaired module back, it now becomes one of your spares.

Now, let’s say you didn’t select a manufacturer that offered spares or, perhaps, offered spares but no U.S. service. What happens when you need to replace a damaged unit? Well, best case scenario, you will be forced to purchase a new module from a different batch to replace the damaged one. The problem is that this new module could very easily stick out like a sore thumb and your brand-new video wall will forever be imperfect.

Worst case scenario, the module you are replacing was from a discontinued model and cannot be replaced. Now your video wall just became a really expensive paper weight! Try explaining that to your customer…

Exertis Almo Has Great Options

Luckily, there are handful of terrific dvLED manufacturers that offer batched spares and support based within the United States. As a matter of fact, some will actually repair and send back your damaged module within 10 business days, in most cases. The point is, you can rest easy knowing that you have a plan in the event of a module failure so your customer will never have to deal with a video wall that is out of commission.

Exertis Almo is the leader in dvLED distribution and we only partner with the best, most reputable brands, because we recognize that your success is our success, and we never want to see any of our customers in a position where they are unable to support a product they purchase from us. We have members of our staff that are dedicated to supporting individual dvLED brands, and they are here to provide you with concierge-level service to help you navigate this new and exciting product category.

So, what’s the moral of the story? Make sure you work with a vendor that offers ample spares and supports their product here in the U.S. to ensure that you and your customer are protected. And to the guys reading this – black is not black. Dress accordingly.

Contact Exertis Almo for product info, inventory availability, or to start a quote.

Coming Up Next…

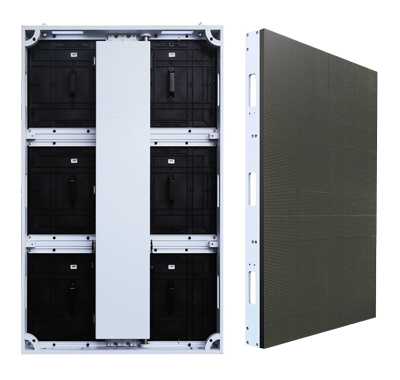

Part 2: Cabinets and Modules and Panels, Oh My!!!

Topic: The anatomy of a DVLED video wall

Part 3: Perfect Pitch

Topic: The importance of selecting the right pixel pitch the first time

Part 4: The First Step in Installing a DVLED Video Wall is Admitting you Need Help

Topic: Commissioning Assistance and why it’s important

Part 5: First Things First

Topic: The importance of proper site prep and conducting a proper site survey

About the Author

Tom Keefe

Business Development Manager

Supported Manufacturers: Absen

by Brian Rhatigan | May 26, 2022 | Digital Signage, DVLED, Pro Displays

One thing that keeps me interested in my career is that our industry is ever-evolving as technologies are introduced and evolve over time. After 17 years of working in the world of Pro AV distribution, I never stop learning new things. Most recently, I was tasked with learning about dvLED to help support our sales team and customers on projects. While I still have a lot to learn, here are some key takeaways that I can share based on what I have learned thus far.

Pixel Pitch & Viewing Distance

The term pixel pitch was new to me, but it is one of the key factors to think about when designing a dvLED display project. Simply put, pixel pitch is the measurement, in mm, between the individual LEDs or pixels, measured from the center of one LED to the center of the LED adjacent to it. Naturally, as the pixel pitch value decreases, the resolution in a fixed size cabinet increases and allows for a closer optimal minimum viewing distance.

For this reason, it is important that you discuss with the client where the closest viewer will be in relation to the display so that you can choose a pixel pitch that is appropriate for the specific application, remembering that as pixel pitch decreases, the equipment cost increases. As a general rule of thumb that has been shared with me, you can multiply the pixel pitch by 10 to give you the approximate closest viewing distance in feet. For example, the recommended minimum viewing distance for a 2.5-pixel pitch wall would be 25 feet.

Resolution

If you are like me, then often when you think about display resolution for common applications it is typically 1080p (1920×1080), WUXGA (1920×1200), or 4K (3840×2160), understanding that there are many others, but these are most common. With flat panel displays and projectors, the image size can vary while the resolution remains constant. For example, a 4K display can be 55” in diagonal, 98” in diagonal, or several other sizes, but the resolution will always be 4K. With projection, a native WUXGA projector, whether displaying a 110” diagonal image, a 216” diagonal image, or any size for that matter, the resolution will always be 1920×1200.

This is not the case with dvLED, as the individual LEDs (or “pixels”) mounted on the surface of the module are a fixed size, so that when the size of a dvLED display changes, so does the resolution. To illustrate this, let’s look at a dvLED panel that is 16:9, 27.5” in diagonal with a pixel pitch of 1.58. The resolution of this panel is 384×216. If you require a 1920×1080 display, you will need 25 panels in a 5×5 array making a 137.5” diagonal display, while if you require a 4K 3840×2160 display, you will need 100 panels in a 10×10 array making a 275” diagonal display, requiring four times the real estate!

Structural Considerations

In many cases, dvLED displays will either be wall-mounted or flown, although sometimes they can be ground stacked with the appropriate stacking hardware. Depending upon the size of the display, they can get quite heavy. For example, a recent 165” diagonal display (6×6 array) I quoted weighed just shy of 500lbs, and a 275” display (10×10 array) weighed over 1300 lbs. It is absolutely crucial that the structure or wall on which you are mounting the dvLED or the structure from which you are rigging can support the load.

Additionally, in order for a successful installation, the dvLED cabinets need to be perfectly aligned along the x, y, and z axes so there are no visible seams between the individual panels that make up the display. Since most walls will have some imperfections and not be perfectly flat, you will be faced with either using shims or exploring mounting hardware that provides post-installation adjustment of all three axes.

Power and Data

Unlike a traditional flat panel or projector, the display does not have a single power cord with dvLED. Instead, depending upon the size and resolution of the display, multiple AC circuits are required. If we go back to the 165” 6×6 array I referenced earlier, this display required six dedicated 110v/10A outlets. In this case, each AC circuit is powering six panels with a main connection to the first, then daisy-chaining with power jumpers to the next five.

In addition to power, every dvLED display requires multiple data connections between the display and the dvLED controller/processor using data cabling, such as Cat6. The number of data runs will vary based on the overall resolution of the display, but you can expect that the manufacturer will advise you during the proposal stage on the required cabling and power requirements for the specific project.

I am seeing more and more projects come across my desk that involve dvLED, and there has been dramatic growth in overall product sales in the category over this last year. There is no reason to believe that these trends will not continue, and I look forward to continuing my education on the subject.

For more information, visit https://www.exertisalmo.com/products/direct-view-led-displays, and get in touch with your Exertis Almo regional service development manager today.

by Adam Coleman | Sep 23, 2019 | Digital Signage, DVLED, Outdoor AV

Image by Absen via Absen Website

Absen’s Senior Director of Sales, Mitch Rosenberg, recently had a podcast interview with MarketScale about the history and future of

direct-view LED technology. Mitch paints an exciting picture of where the industry is heading, explaining in detail how we got here.

Full-spectrum direct-view LED initially came out the gates in the late 90’s, with a pixel pitch and cost that made it available only to very large venues where the audience was 50-100 feet away. As the technology has evolved, it’s now becoming the dominant digital display technology with no signs of slowing down.

Direct-view LED was once a very expensive display, requiring special content and engineers to get running. It’s now light-weight, easily configured, easily serviced, and has fine pixel pitches. Mini-LED and micro-LED technology will bring those pixel pitches down to around the same as a laptop monitor, with a durability that fine pixel pitches have never before had. Building on the same robust backbone, direct-view LED displays will continue to thrive where they’ve already been adopted, and will enter new markets previously not appropriate for dvLED.

Where other technologies have reached their optimization, dvLED will continue to advance into the future. Hear Mitch’s thoughts on the industry, the evolution of direct-view LED, and why anyone wanting a display should only be looking at one solution.