by Todd Heberlein | May 4, 2018 | Digital Menu Boards, Digital Signage, Pro Displays

A digital signage content management software

that ✓ all the boxes.

Clients looking for a digital signage solution often have very similar feature sets that they are seeking. In the past, there were some features that our solutions could not provide, so the client would need to make some sort of compromise instead of being able to check all the boxes on their list of needs. Since the addition of Zebrix to the Almo line card, compromises are now few and far between.

Let’s take a look at what Zebrix offers that allows us to check off some of commonly requested features that were previously out of reach.

Hosted, web based CMS

Having a hosted, web based content management system (CMS) offers some advantages over an “on premise” solution. It reduces the amount of time that IT professionals would spend evaluating security and managing a software installed on local servers, which allows them to focus on their day to day workload.

One of the other great advantages of a hosted CMS is the ability to manage the content from any device, anywhere internet access is available. Since web browsers are ubiquitous there is no need for a specialized device to manage content or to provide access to players.

Also, because the software is in the cloud you can manage players located all over the world.

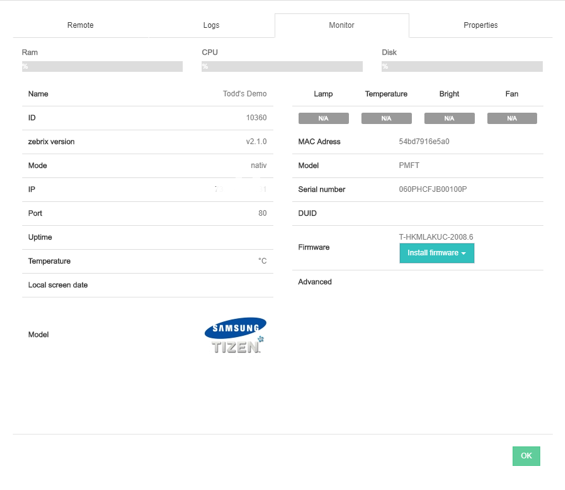

No need for additional player hardware

With the introduction of powerful “system on a chip” processors in commercial displays, like Samsung’s Tizen processor*, Zebrix is able to offer PC-like performance without the cost of an external player. Savings can be parlayed into larger displays, or additional displays for a project.

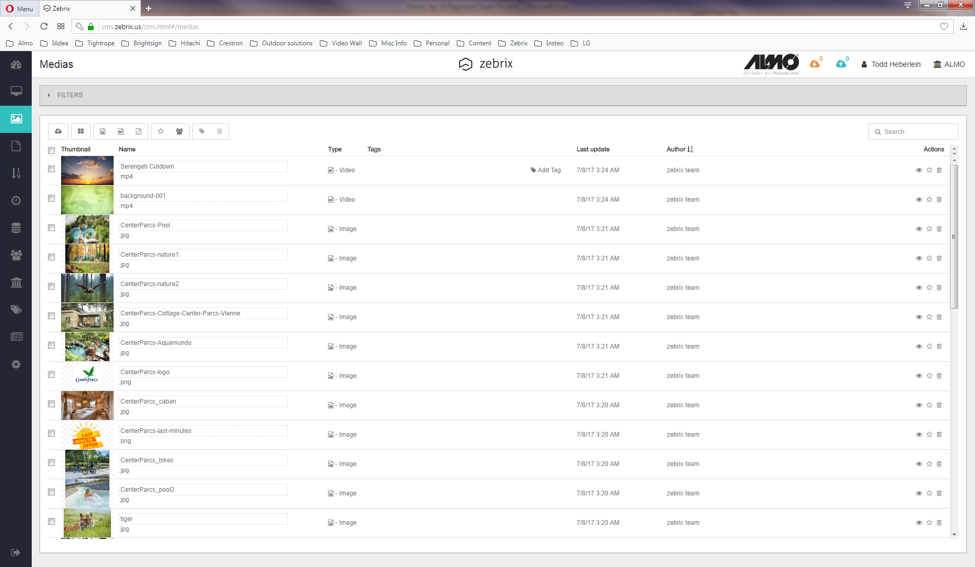

Intuitive CMS interface

Ok, so this may not be exclusive to Zebrix (Almo Pro AV offers other solutions with this feature), but they take it to a whole new level. Since Zebrix is web based, it offers the ease of use and functionality that people have come to associate with purpose made “apps” on mobile devices. With drag and drop content upload, and WYSIWYG design features, creating professional looking signage becomes easier than ever.

Display management and live view

Because Zebrix uses the internal player on the Samsung Tizen based displays, it becomes easy to manage the display as well as see a snapshot of exactly what is playing on the display at any time…all with the click of a button.

If you’d like more information on the features Zebrix offers, or to demo of the software, please feel free to contact me using the contact information below.

Todd Heberlein

888-420-2566 x6205 | [email protected]

*Currently, only Samsung’s internal player and a Ubuntu external player work with Zebrix.

by Todd Heberlein | Apr 17, 2017 | Digital Signage, Hospitality

Have you ever looked at two seemingly similar items on the shelf of a store, or more likely, two similar items on your Amazon wish list, and wondered, “Why is one more expensive than the other?” I know I have. With Amazon, it’s easy to use the online reviews to help determine the difference in value, but in the Pro AV world, it can be a bit more difficult.

Recently, I had the opportunity to see first-hand how one manufacturer adds significant value to their products. Most of the difference comes in the form of ease of use and reliability, but some of the value goes even deeper.

Crestron has been known for the quality of their products since as long as long as I can remember. When you install Crestron products into your AV system, they just work, and work well.

Last month, Brian Rhatigan (Almo BDM Director) and I visited Crestron’s facility in New Jersey, and were treated to a day of hospitality and education. Not just an education on Crestron’s product line, which I felt I knew pretty well, but rather an education on their company focus – quality. Not just a quality in product, but also a quality user experience.

We were fortunate enough to have Dave Silberstein, Crestron’s Director of Inside Sale, set aside an entire day to provide us with a guided tour of their facilities, along with a visual summary of their research, design, and manufacturing process from start to finish. I’ll go ahead and speak for Brian here when I say, we were impressed.

A couple of things really stood out for me, besides the quality of their customer experience center (You could throw one heck of a party in there).

Here are some highlights I wanted to share:

Crestron has an entire staff of engineers devoted to the design of new products. Currently 40% of their net profit is put back into their R&D department, and what a department it was. Some of the brightest minds in the industry are working on developing the next piece of cutting edge technology. And they have some of the best “toys” to play with. From flow jets to 3D printers and beyond, they have the tools to develop every component of a prototype.

Their testing facility was incredible. One fascinating sight was an enormous system of their current and past products. The system is primarily used to test any software / firmware due to be released, to verify that it doesn’t have any adverse effect on older systems still in use. This is something I appreciated as it seems like each firmware released on my phone brings it closer to its demise.

Another impressive sight was the “wall” of 100 displays being used to test a video conferencing system with 100 end points. It seems that testing, let’s say, 10 endpoints would be acceptable, but fortunately for Crestron’s clients, acceptable is just not good enough.

Their technical support is provided regionally to better understand and support their local customer’s needs. This isn’t so special, but what was, is each technician has a full system located at their desk. It made for a crazy looking workspace, but it allows each technician to actively participate in the troubleshooting process, instead of just searching for a solution in their knowledge base. In addition to this, older items are located just a few steps away, so the technician is able to grab whatever is needed to try and duplicate what is being used in the field. We even spotted a slide projector controller in this “closet of technology past” – something that harkens back to the roots of where Crestron began.

It’s hard to put into words just how impressive the Crestron facility is, and how dedicated they are to producing a quality product. Luckily their long run of producing excellent, industry leading products has created a reputation that our industry already equates with quality.

by Todd Heberlein | Aug 8, 2016 | Video Walls

One of my favorite things to design has always been video walls. I love the flexibility they offer. I’ve “worked” on a variety of projects: A basic 2×2 with a single input source, a multi-sized display wall that was shaped to mimic the LA skyline, to a 90+ unit monstrosity with hundreds of input sources. (Notice that “worked” is in quotes) Working for an audio visual equipment supplier, I’ve had the opportunity to partner with various integrators, but have rarely had the opportunity to get my hands dirty. Coming from a background in construction, I always loved the feeling of building something and felt a bit jealous of the installers who got to see the end result first-hand. Sure, living vicariously through shared images is marginally enjoyable, but it’s tough to fully appreciate the work or satisfaction that comes from creating something on your own.

Recently that changed. During Almo’s booth setup at Infocomm, I was finally able to get a little more of the installation experience, and I was in for a rude awakening. The design was put together by Brian Rhatigan, another BDM with Almo, but it was up to me to bring it to life. I was actually excited. In the past, I’d helped on a few basic walls for trade shows, but they’ve always been relatively straight forward, with few or no surprises. Not this one. This one was in the shape of a pinwheel, and I really had no idea where to start. We had sketched out a basic design, with a few measurements based on the mount we were using (Peerless DS-VWM770). The measurements were based on a spec sheet, since the mount was recently released, and I had never even seen it before. I was still excited….but now with a hint of trepidation. I didn’t think it would be too big of a problem with all the adjustment knobs, etc. that come on the mount. I figured I’d knock it out in a couple of hours, tops. WRONG! Even with all of the adjustability, the entire project took the better part of a day to complete…for 4 measly displays.

It goes to show that no matter how good products are (this mount was awesome for this project), there is no replacement for experience. The good thing is, I came away with a better appreciation of what an installer can go through…and more than ready to get back behind my desk where I belong.

by Todd Heberlein | Jun 3, 2016 | Digital Signage, DVLED, News, Uncategorized

There are many factors that go into choosing the correct LED sign, but a few important attributes are commonly ignored. Below are three commonly overlooked factors that should be considered when deciding on a sign manufacturer.

1) Operating Cost

Capital expenditure, or initial investment cost, is typically the first and the most influential factor that most decision makers consider. What many overlook or only give a passing consideration is the ongoing expense of the sign. The larger the sign, the more important this factor becomes over the life of the sign. Knowing that you’re installing an energy efficient sign can save you tens of thousands in operating expenses down the road.

2) Ease of Use / Management

Signs that require proprietary software, or require the purchase of third-party software can add frustration for the end user, a large learning curve, as well as push up the total cost of the project. ADTI offers the flexibility of using their included content management system, SkyShow, or any signage solution that can utilize their standard HDMI input on the SkyPanel system.

3) Ease of Installation

This is a factor that is commonly skipped over, and almost never is considered by the end user. Since it ultimately affects the bottom line, as well as the timeline of the project, I think it’s an attribute that deserves consideration. If the installation requires special structural changes because of the weight, fabrication to enclose the sign for weatherproofing, or modification to allow for extra depth, the money you saved on the lower cost hardware shrinks considerably, or is completely wiped out.

ADTI

The difficulty of measuring the increase in quality in comparison to the increase in cost, can cause endless hours of agonizing research, and can freeze the final decision. Many are drawn in by the low cost LED panels they’ve seen coming out of China, and end user’s tend to lean towards the frugal choice for the initial capital expenditure and ignore the ongoing operating expense of running an LED sign; which can be an expensive mistake. With ADTI, you don’t have to make that compromise. The combination of affordable initial cost, American made quality, IP67 weatherproofing, and incredibly low power consumption, makes for a visually stunning, “no compromise” solution.